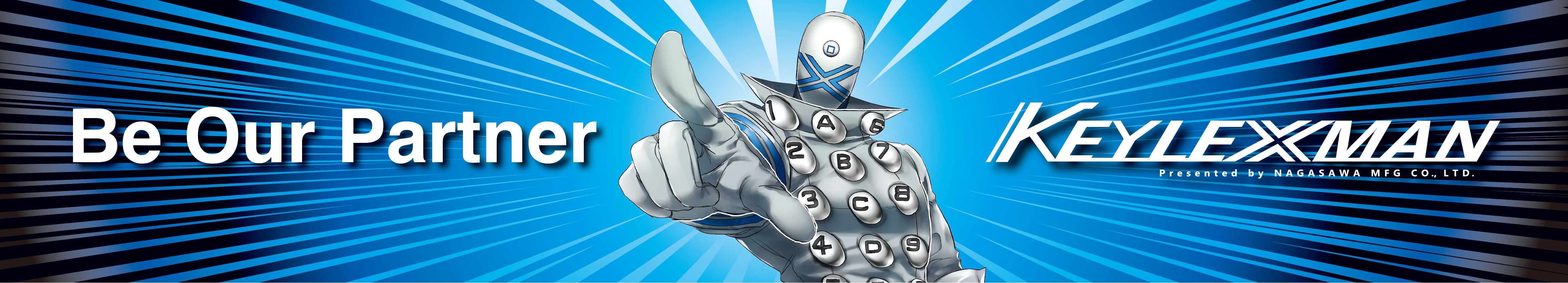

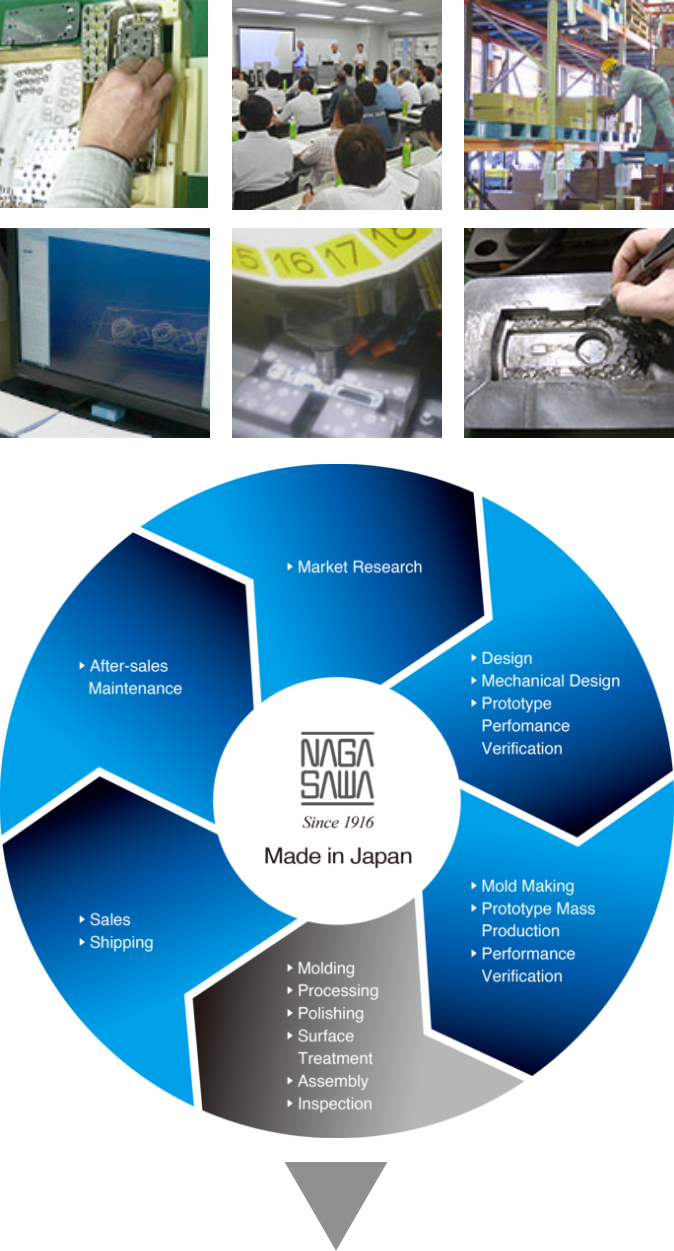

Nagasawa Manufacturing Co., Ltd. has established an integrated line of planning, production, sales, and after-sales maintenance.

Business Cycle

About the integrated production process

-

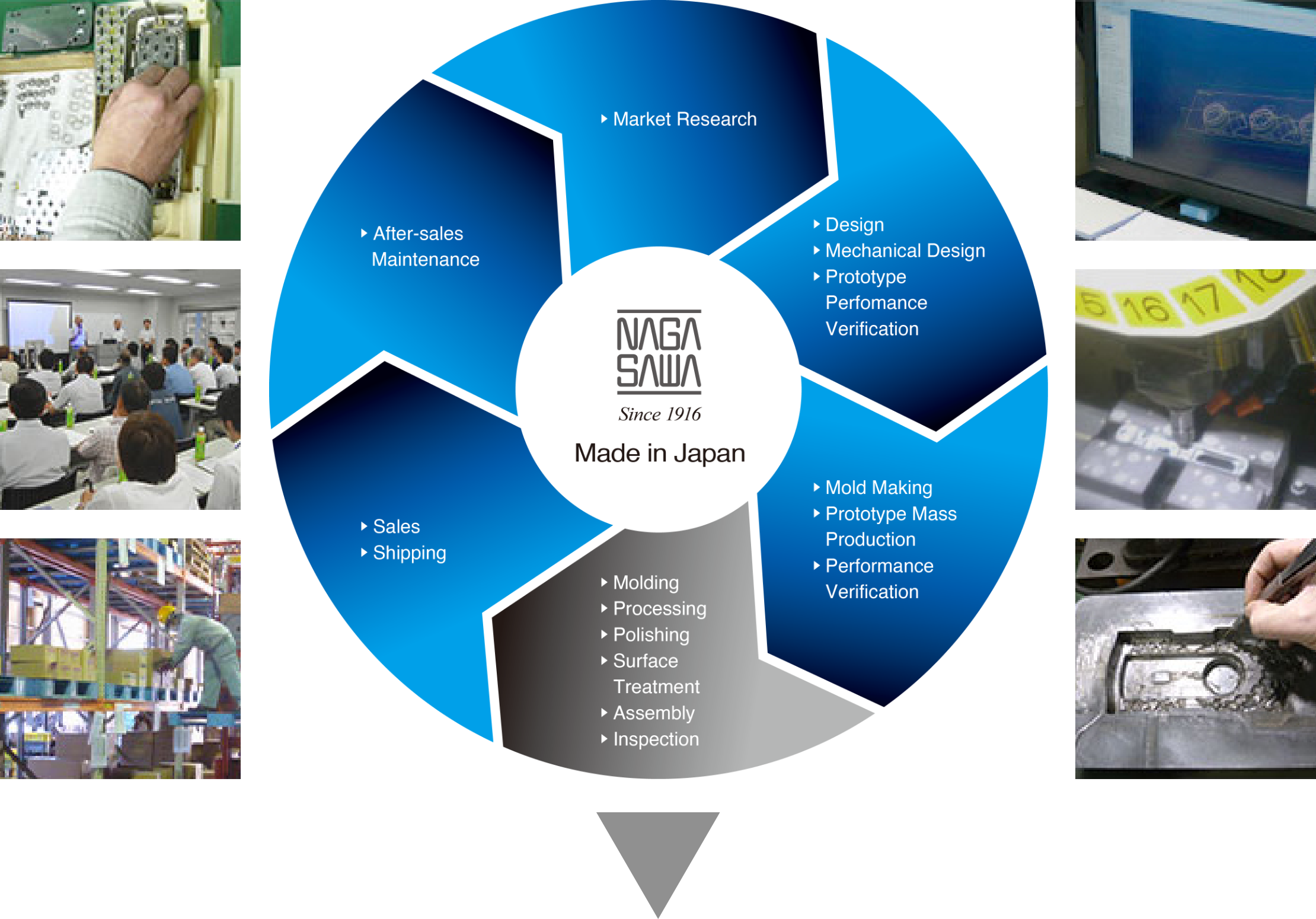

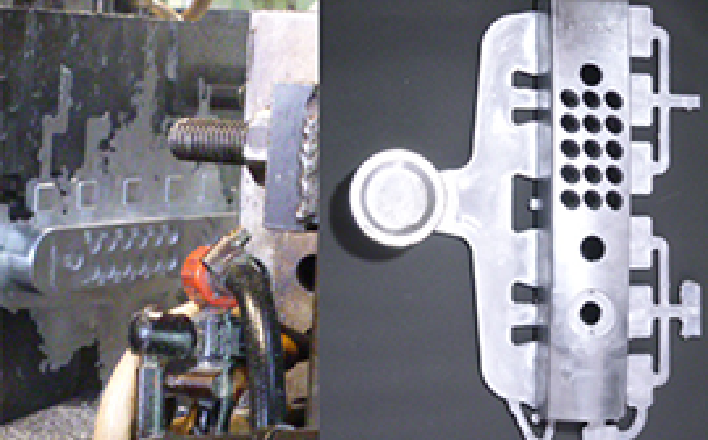

Parts are formed by die casting machine

-

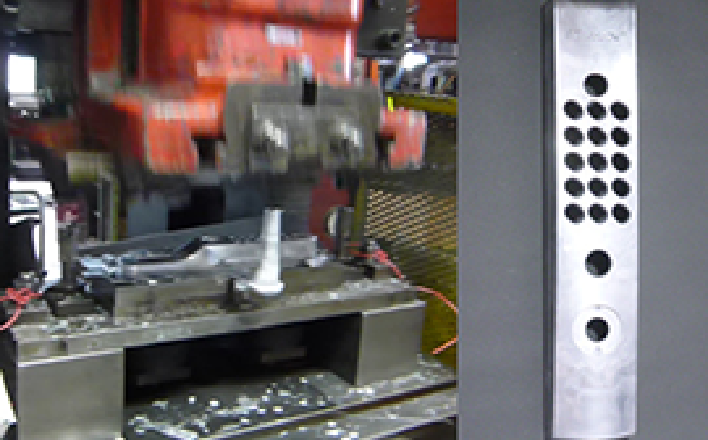

Unnecessary parts are removed by a press machine.

-

Polishing process suitable for surface treatment is performed

-

Coats metal to improve surface hardness and texture.

-

Hairline polishing and color matching are performed by buffing.

-

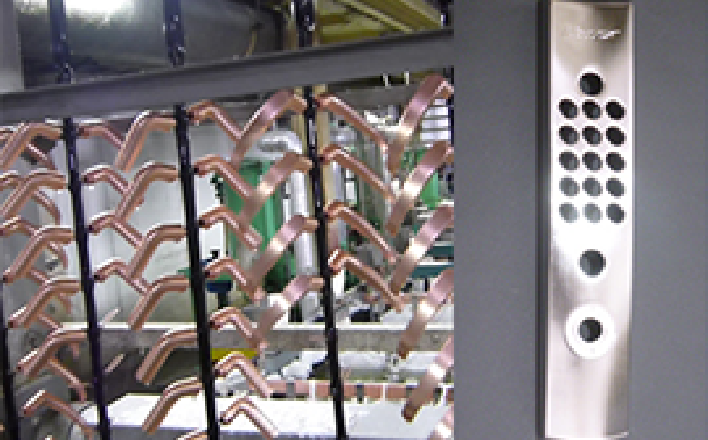

Painting is performed by a painting robot with even coating thickness down to the smallest detail.

-

Color coating is performed to bring out the metallic luster of the material.

-

Assembling parts and inspecting operation.

-

Pack the product, attached parts, and instruction manual.

Quality Policy and Environmental Policy

Quality Policy

In all operations at Nagasawa Manufacturing Co., Ltd. it is our principle to follow the spirit of our management philosophy: “We will always be ahead of the times and continue to produce original products that are safe, reliable, and dignified for end-users to use.

To this end, we aim to constantly improve quality in all aspects of our operations, including product development, manufacturing, sales, and service.

In addition, with “zero claims from outside the company” as our primary goal, we will strive to strengthen and improve our manufacturing and technical capabilities in order to ensure more attractive quality, while thoroughly preventing the recurrence of problems and preventing them from occurring.

[Applicable Standards] ISO 9001:2015, JIS Q 9001:2015

Certification acquired on 2007/04/06

[Certified office] Head Office, Tokyo Branch, Osaka Branch

[Scope of Certification] Design, manufacture, and sales of architectural hardware

Environmental Policy

– Basic Philosophy

Nagasawa Manufacturing Co., Ltd. recognizes that preservation of the global environment in harmony with nature is one of the most important issues on a global scale, from the present to the future, and we will strive to preserve the global environment by promoting the reduction of environmental burdens through our business activities, including product development, manufacturing and sales.

– Action Guidelines

We will comply with environment-related laws and regulations, regulations of industry associations, and agreements with customers and neighboring communities.

To promote environmental preservation activities and prevention of environmental pollution, we will establish an environmental management system in accordance with ISO14001 and continuously improve it.

We will promote energy conservation, resource conservation, and resource recycling to protect the environment and prevent environmental pollution.

In order to promote this environmental policy, we will set appropriate environmental objectives and targets, which will be systematically and continuously reviewed and improved.

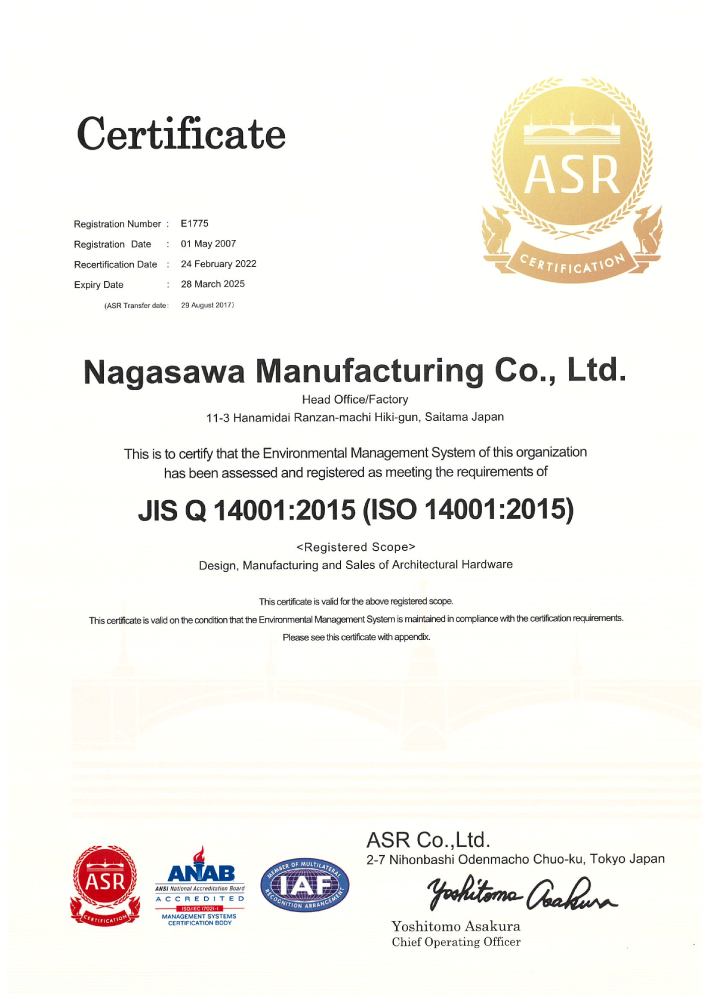

[Applicable Standards] ISO 14001:2015, JIS Q 14001:2015

Certification acquired on 2007/05/01

[Certified office] Head Office, Tokyo Branch, Osaka Branch

[Scope of Certification] Design, manufacture, and sales of architectural hardware

Practical Performance Accreditation System JLMA Testing Laboratory

The Japan Lock Manufacturers Association (JLMA), of which we are a member, strives to operate a “Practical Performance Certification System” that enables the standardization of product quality and appropriate product selection for the conditions of use.

In 2014, we established a testing laboratory to constantly monitor, supervise, and evaluate whether the performance of products manufactured and sold comply with JIS standards and meet quality grades, and obtained approval as a “Product Performance Testing Center” after a rigorous examination. In operating the Product Performance Testing Center, we have also strengthened the management of facilities and the training of test personnel, and are contributing to the stable supply of even higher quality products based on safety and security.